blog

Can the Darkest 5% and Lightest 70% Window Tint Both Block Over 80% of Solar Heat? | GLASSTINT Rode Ceramic Tint

- 2024.08.15

- Martin. C

The Origin of Ceramic Tint in the Sunbelt, USA

The window tinting industry has thrived in the Sunbelt region of the United States, encompassing states like Texas, Florida, Arizona, and California, thanks to the warm and sunny climates. The intense sunlight and high temperatures experienced year-round in these areas have increased the demand for window tints that reduce heat, glare, and UV rays in buildings and vehicles. Tinted windows not only lower cooling costs but also protect interiors from sun damage and enhance privacy. This industry has evolved with advanced technologies like ceramic and nano-ceramic tints, offering superior heat rejection and clarity. As energy efficiency and environmental concerns grow, the window tinting industry in the Sunbelt, particularly the ceramic tint sector, continues to expand, serving both residential and commercial markets. Let’s explore how the remarkable features and capabilities of GLASSTINT Rode film could revolutionize the qual

Rode Shatters Conventional Beliefs About Tint Density and Heat Rejection

It is commonly believed that darker window films offer better heat rejection, while lighter films are less effective. For instance, take Brand A’s ceramic tint as an example. On their website, the IRR (Infrared Rejected) values for various tint shades are typically listed, showing that lighter shades generally have lower IRR numbers. However, in January 2018, Rode film was introduced, proving that regardless of the visible light transmission (VLT) or tint shade, it can block 80% of infrared rays, the primary source of solar heat. This breakthrough technology, achieved by reducing metal into non-metallic nanoparticles, sparked a revolution in ceramic tinting.

Where Does GLASSTINT Rode Rank Among Ceramic Tints?

GLASSTINT’s nano-ceramic tints are categorized into five grades. These tints are fully non-metallic and non-reflective window films. The five grades are classified based on the level of infrared solar heat rejection, with the product lineup including GLASSTINT Pender, GLASSTINT Rode, GLASSTINT Santana, GLASSTINT Shure X, and GLASSTINT Camo. Although Rode is the second from the bottom in GLASSTINT’s internal ranking, it’s essential to note that within the broader market of over ten window film grades, it ranks in the upper-middle range, offering high specifications and performance.

Who Benefits From Using Rode Film?

Customers who assume that light tinting is ineffective will be pleasantly surprised by this film’s utility. In typical tint shops across the U.S., simply asking for a ceramic tint can lead to disappointing results. Be sure to inquire about the brand and check the film company's website for detailed information. After finding the product name, look up the Total Solar Energy Rejection (TSER) and Infrared Rejection Rate (IRR). Remember, the figures presented are the results of in-house tests conducted with just the film, so real-world performance might vary slightly. When driving in direct sunlight, a realistic IRR of 60% or higher can make a noticeable difference. Rode offers an 80% heat rejection rate, which can significantly improve comfort by reducing the interior temperature by 30-40%. While it’s essential not to equate the 80% rejection rate with an 80% felt reduction, Rode’s ceramic tint can enhance driving comfort by over 30%, which is a considerable benefit for those who spend a lot of time behind the wheel.

Why Is GLASSTINT Film Liner Wound Inside the Roll? | Tinter Tip 1

Roll Winding Direction: GLASSTINT tint rolls are wound in reverse, with the film liner rolled inside. This unique design helps prevent the film from lifting at the edges after squeegeeing when installing on windshields, back glass, and frameless windows from the interior. This issue, often seen as a natural and unsolvable phenomenon, is fundamentally addressed by this method. Tinters will quickly become accustomed to installing these reverse-wound tint products and understand why the liner is rolled inside.

Tinters understand the term “curling.” This wasn’t a problem or an issue for tinters to overcome. Car windows were mostly flat 20 years ago, so curling wasn’t an issue. However, with the advent of curved glass, manufacturers have not adequately addressed the lifting problem during film installation. For windshields or rear windows with extreme curvature, the fundamental way to reduce the lifting phenomenon is to use GLASSTINT rolls with the liner wound inside. The problem was never the tinters’ fault but rather the lack of detailed attention from film manufacturers over the years, leading to unnecessary trial and error.

Rode Film Adhesive, Heat Shrink, and Hard Coating Type | Tinter Tip 2

Rode's heat shrink may feel slightly slower, but don't worry—it's a minimal difference. This slight variation results from the adhesive's composition and strength, the thickness of the hard coating for durability, and the slip level. These factors can cause tinters to experience different heat shrink behaviors. GLASSTINT adhesives do not transfer to the glass when the film is removed. The adhesive is soft but not overly rigid. This means the film might retain heat slightly longer during heat shrinking, especially in higher heat rejection films. We have developed a hard coating that is slippery, preventing almost all scratches from plastic squeegees. It's recommended to maintain horizontal balance when handling the roll by hand, as tilting could cause the film to unwind.

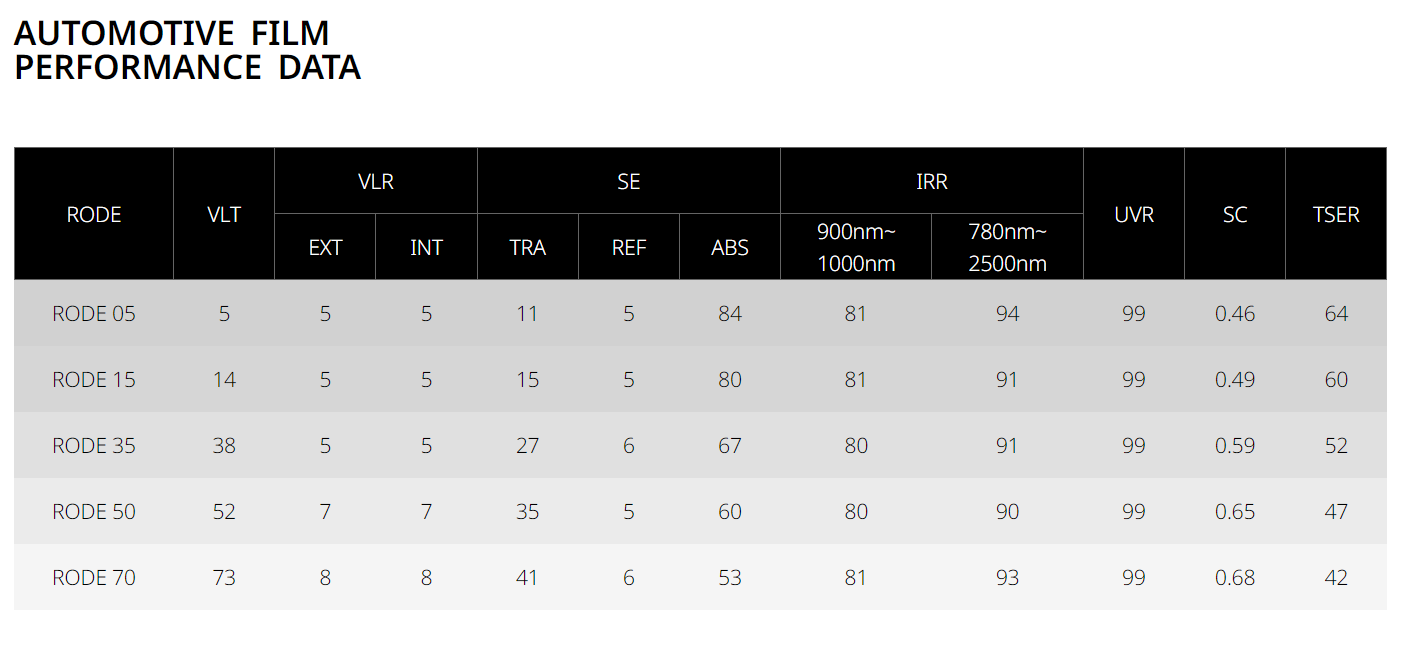

Rode Ceramic Tint Performance Data

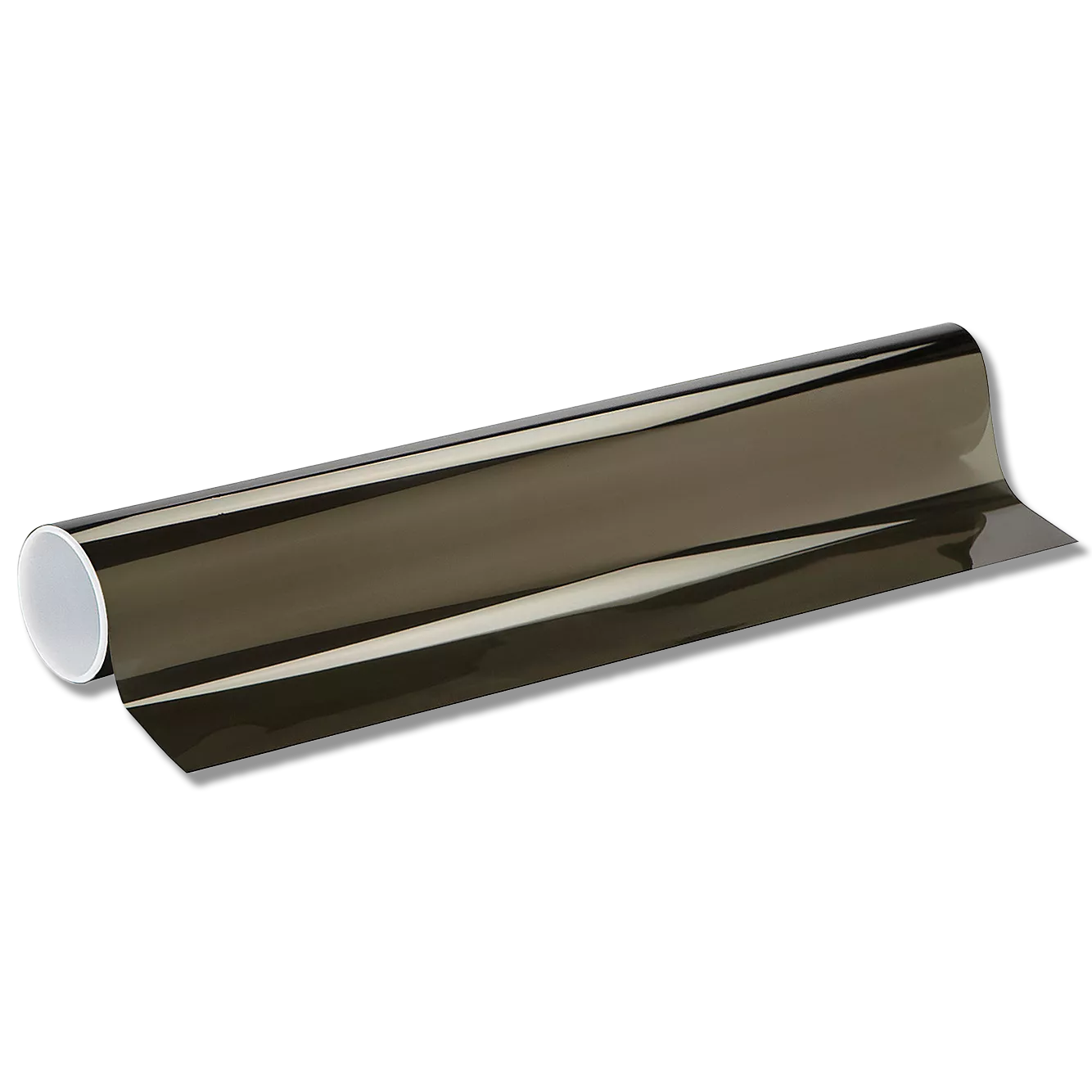

Rode Ceramic Tint Film Color

Rode has a dark blue tint, but this color is not significant once applied. From the outside, the tint appears black, while from the inside, the view is natural with a subtle blue hue. The film’s color is almost unnoticeable unless the car door is opened and the tint is closely examined. Essentially, it provides a natural look.

Imagine how your car will look after installing Rode tint by referring to the photos below

Pender

Pender

Rode

Rode

Santana

Santana

Shure X

Shure X

Camo

Camo

Sunset R

Sunset R

Reiney Blue

Reiney Blue

Aura

Aura

Aero Shield 500

Aero Shield 500

Aero Shield 700

Aero Shield 700